Carbon neutrality is a popular goal among technology companies. Google has been a trailblazer in this effort, achieving zero carbon emissions in 2007 and claiming to have erased its entire carbon footprint as of 2017.

Since then, many semiconductor companies have committed to this altruistic goal, aiming to reduce annual emissions by 30%.

WBG Semiconductors and Carbon Neutrality

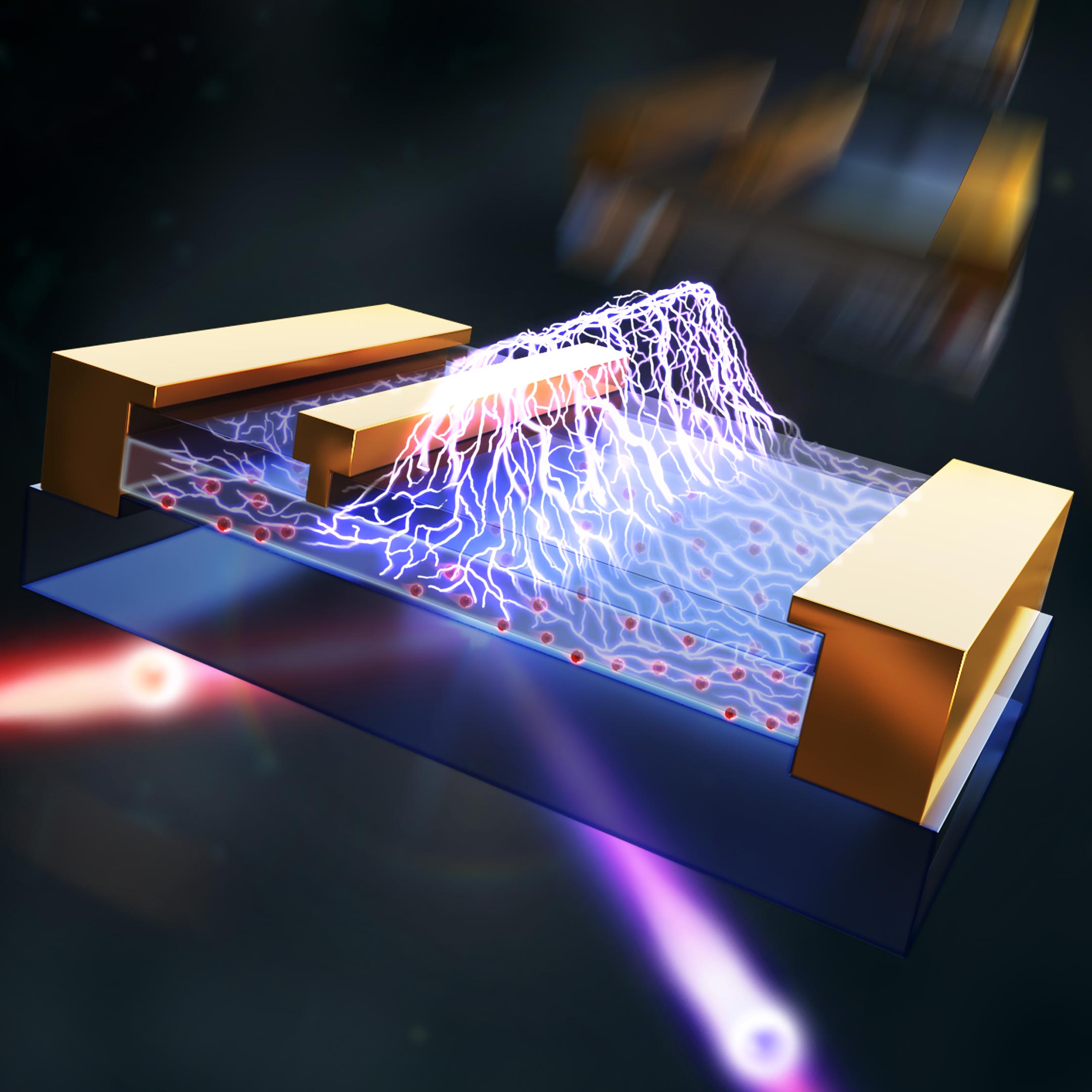

WBG Semiconductors have a greater valence-band-to-conduction-band energy gap than silicon. As a result of this property, WBG semiconductors can operate at higher temperatures and voltages than silicon.

The ability of SiC power devices to improve energy efficiency in electric vehicles is making headlines, and portrayal of SiC technologies as an important aspect in a decarbonized society is one such example. Researchers see SiC power semiconductors as a key enabler in expanding the use of EVs, which is critical for lowering CO2 emissions.

WBGs provide improved energy efficiency of power conversion, which is an important benefit in terms of carbon neutrality. WBGs have been shown to have up to 10% higher power conversion efficiency than silicon counterparts, which can make a significant difference in high-power applications such as vehicles and data centers.

Furthermore, the ability to operate efficiently at high temperatures is critical. Wide bandgap semiconductors can be used at higher temperatures than silicon, but they also require less cooling resources.

Given that cooling can consume up to 55 percent of a data center’s total energy expenditure, it’s easy to see why wide bandgap semiconductors are so appealing to environmentally conscious businesses.

Sic And Green Ambitions

Silicon carbide semiconductors are becoming a pillar in many semiconductor companies’ efforts to implement green technologies. SiC’s advantages in supporting EV designs in high-temperature, high-frequency, and high-voltage environments are now widely acknowledged when compared to silicon power semiconductors. Furthermore, SiC has a low resistance when compared to silicon, allowing electric current to flow freely even at higher frequencies.

As a result of Tesla’s trailblazing decision to include SiC components in Model 3 vehicle’s traction inverters, SiC MOSFETs are gradually replacing the silicon IGBTs in EV power modules. While Tesla demonstrated the performance advantages of SiC components in traction inverters in 2018, Toyota demonstrated SiC’s value proposition in Prius PCUs in 2014.

The gap between the silicon and SiC worlds is closing, as evidenced by the increased interest in SiC devices in EV designs. At a time when CO2 emissions are a major driver for vehicle electrification, proponents such as Tesla and Toyota demonstrate its suitability in high-temperature, high-frequency, and high-voltage environments when compared to conventional silicon.

The fact that many companies consider SiC semiconductors to be a major contributor to a low-carbon society is an important endorsement for this promising WBG technology.

Impacts on the Engineer

As more businesses begin to work toward carbon neutrality in the near future, it appears that investments in wide-bandgap semiconductors will only grow. These developments may influence future design decisions as a practicing engineer.

With more money being invested in the development of WGBs, it is only a matter of time before these components are mature enough to be interchangeable with traditional silicon. It may be worthwhile to consider replacing silicon transistors with WBG counterparts in order to design systems that are more energy efficient.