Equipment maintenance can be expensive, both financially and in terms of time. How can you maintain competition and make a profit (ROI) from your investment? In this section, we briefly discuss administrative strategies and technology advancements that are used to cut down on equipment and maintenance downtime.

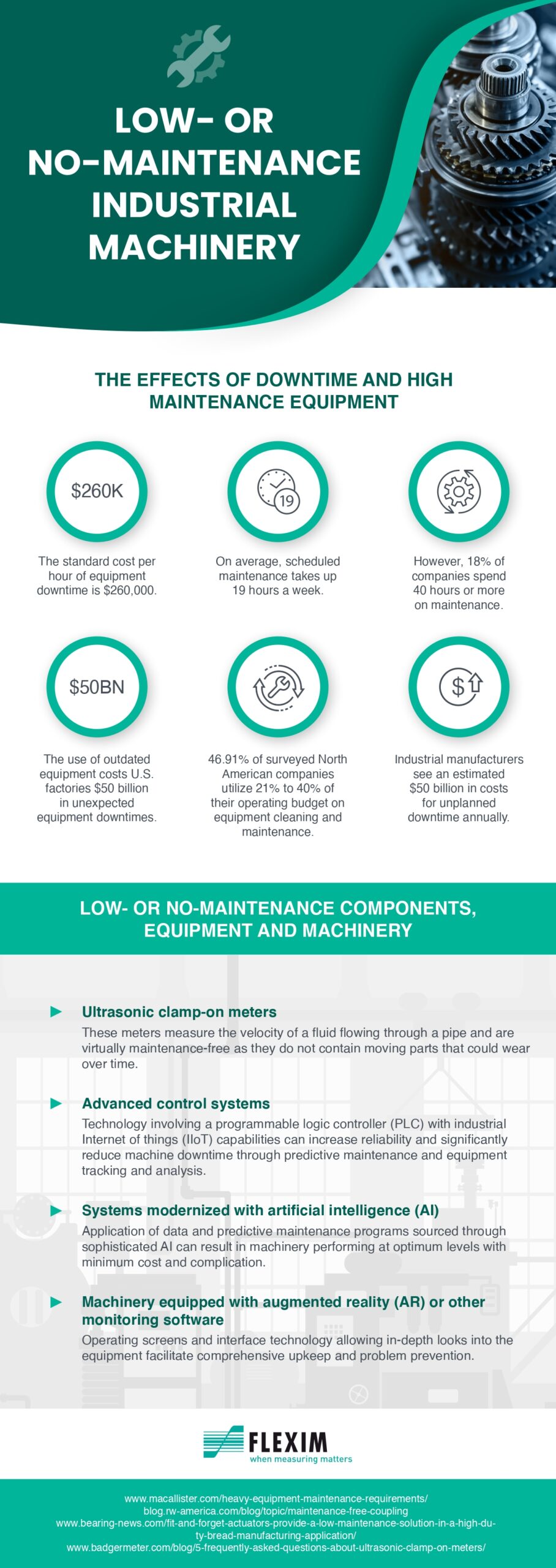

By 2026, the market for maintenance, repair, and operations is anticipated to reach $701.3 billion. A few different variables in the industrial settings influence this high cost. Unplanned downtime is mostly caused by out of date resources. Unscheduled equipment downtime, according to maintenance experts, can be brought on by mechanical failure, operator error, a lack of sufficient maintenance time, and poor design.

A great strategy to save maintenance costs is to use parts that need little to no maintenance. Ultrasonic clamp-on meters are one example. Because they have no moving parts that can wear out over time, these meters are used in a number of situations, including the water distribution industry. They are made to need little, if any, maintenance.

Another technique to increase ROI is by developing an extensive preventive maintenance (PM) strategy. In fact, preventive maintenance was regarded as the top priority for 2020 by 76% of industrial businesses. This strategy seeks to spot possible issues early on and deal with them. Thus, PM contributes to lowering downtime, extending equipment life, and raising resale value. However, the type of asset affects the overall cost of ownership.

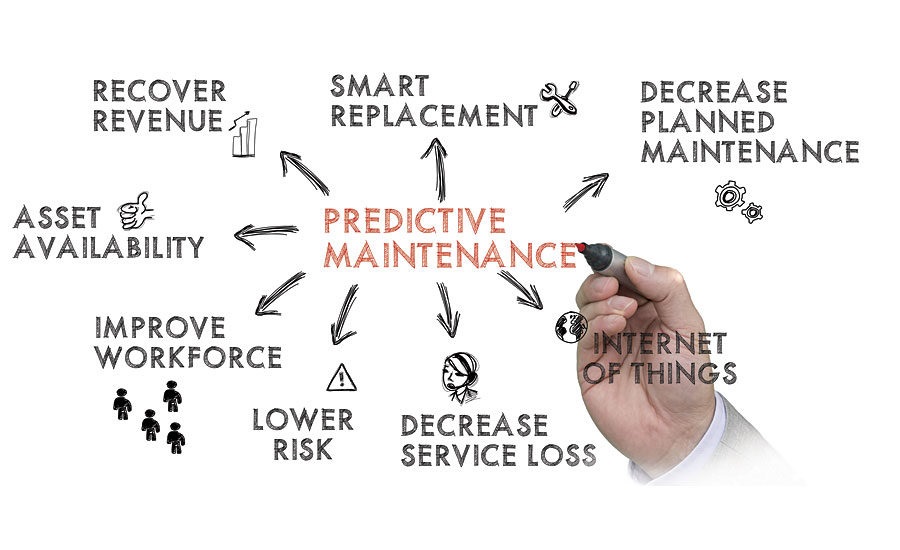

Analytical technologies are also used in predictive maintenance. According to studies, 41% of industrial companies already use this tactic. Despite being pricey and new, predictive maintenance is reportedly quite cost-effective. According to the US Department of Energy, it can save between 8 and 11% when compared to preventive maintenance. Experts also predict that by 2024, the global market for predictive maintenance will be worth $23.5 billion.

The key is predictive maintenance (PdM). Predictive maintenance provides updates and analyses the condition of the machinery that is now in use utilizing software, sensors, and artificial intelligence. It is possible to forecast when equipment will need maintenance based on this information. When compared to routine or time-based preventative maintenance, this strategy aims to reduce costs by only taking action when it is absolutely necessary.

The chore of managing maintenance is challenging. However, by integrating new technologies, updating to low- or no-maintenance components, and employing the proper tools for the job, it is possible to extend the lifespan and performance of everyday equipment.

For more information on upkeep and workable alternatives, see the accompanying infographic.