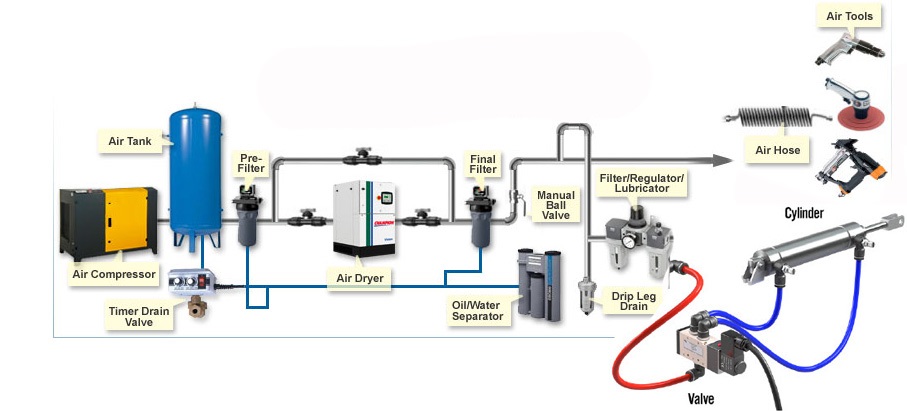

Usually air is pumped into a recipient by means of a Festo Pneumatic. A large amount of compressed air is in the container, which is used when necessary by the pneumatic system. The ambient air includes airborne pollutants, water vapor and other toxins, so that filters and air dryers also work in pneumatic systems to keep the compressed air clean and dry to increase the efficiency and durability of components and devices. In order to control direction, precision and speed of actuators using different valve systems, pneumatic systems are also used.

Where Are The Pneumatics Used?

While most of us do not know, we are surrounded by pneumatic systems. Some examples are below.

Bus and truck air brakes are officially called compressed air brake systems. The systems use a friction brake that forces the air down on the piston, then twists the brake bag to stop the vehicle.

Training machines on pneumatic systems can be installed. The air pressure can be adjusted to the pneumatic cylinder resistance.

Compound air engines, known as pneumatic motors, operate through the expansion of compressed air mechanically. The compressed air is typically converted by rotary or in linear movement to mechanical motion.

Pressure controllers are valves intended to stop the flux of a fluid or gas automatically when a certain pressure is reached.

Pressure sensors are used for calculating gas or liquid pressure.

Pipe organs produce sound by pressing pressure air on pipes selected using keyboard presses.

Inflatable structures like balloons, bouncing chateaux or blow-up numbers, such as helium, hydrogen or air, are inflated by gas. The gas pressure maintains an inflation of the structure.

Cable jetting is a method that allows cables to be placed in ducts. Compressed air is entered into the pipeline and flows along the wiring.

Air tube pressurized pneumatic mail systems deliver letters. In the 1800s a Scottish inventor invented it.

Gas compressors are machines that reduce their capacity, increasing the pressure of the gas.

A pneumatic bladder can be used for the screening of drains and ducts for the purpose of containing chemical gasses or spills, for stabilizing cargo in a recipient or to float an artificial coral bottle. These are suitable for use in medical research and other applications.

The power of compressed gas is used by pneumatic cylinders for generating pressure.

A vacuum pump extracts gas from a jar which is screened, leaving a partial vacuum behind it. Invented in 1650, this concept.

When a certain amount of pressure has been reached, pressure switches close an electrical contact. The switch can be set to contact when the pressure rises or the pressure drops.

Pre-compressed air is used as an energy source by pneumatic air pumps to trigger the projectile.

In a closed chamber, barostat systems keep constant pressure. It is suitable for medical use.

Recharging with gas supplies firearms with energy.

The pneumatic tires are made of compressed air and formed on a bike, car or other vehicle to inflame the body of a tire. You can find the best pneumatic components in Festo Dealer in India.